Overhaul / Repairs / Upgrades

Here at CRI we can offer repairs, modifications or replacements to equipment which is under performing or in need of some routine maintenance. During site surveys and client discussions we can offer suggestions and recommendations to improve existing systems and processes to maximise customer up time and productivity.

All of our Engineers and Technicians have been fully trained by Fisher and Flowserve so you can rest assured that your equipment is in safe hands.

When it comes to repairs, we always offer OEM spares in the first instance and when necessary – and only with written client approval and agreement – we can supply non-OEM parts to speed up the repair process.

We have full use of the Fisher IBT system which gives us live prices and deliveries meaning we can provide quotes quickly and efficiently meeting our customers needs.

We offer a full guarantee and warranty against faulty workmanship or materials.

Workshop Capabilities

CRI have recently just moved to a new purpose built valve workshop designed to allow for safe and efficient working on all types of Control Valves, Isolation Valves and Relief Valves.

The workshop has the capabilities of overhauling up to 20inch Control valves and 36inch Ball valves aswell as in house testing once the work scope has been completed.

Every valve that leaves the workshop will have been rigorously tested to all the recognised standards like API 6D, ANSI/ISA 75.19.01-2007 & FCI 70.2 to ensure it passes the Tests and meets these high standards.

Below are the typical stages of an valve overhaul at our workshop:

Initial Inspection and Review

Firstly the details of the valve and any instrumentation is noted down and loaded onto the system. We have a bespoke Valve Management Database (VMD) where every job is loaded on to the system to give real time updates of the progress of the valve as well as all the details of the valve.

Pictures are then taken of the valve before carrying out a function test and seat test with the results taken down in VMD.

Strip Down and Review

This will determine the condition of the valve but also the specific parts like the Trim and Seals. The conditions of the parts will be updated on the VMD with recommendations along with photos of any damage found.

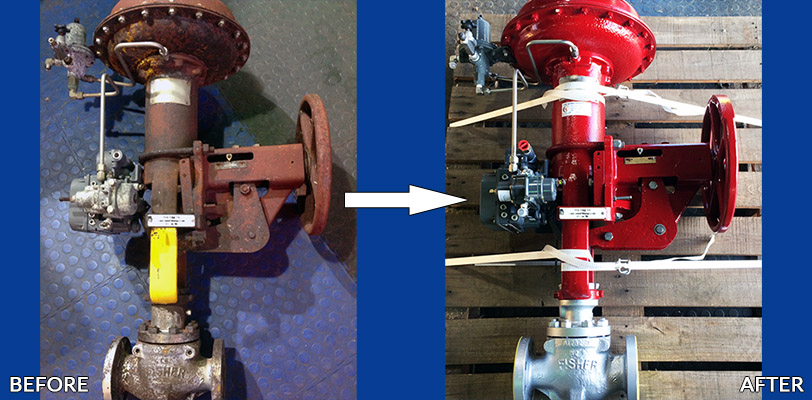

Shotblast and Paint

The valve will be completely shot blasted and cleaned up before being painted.

Reassembly

The valve will be rebuilt using all new soft spares and any other spares needed to return the found to a good working condition. If additional spares are needed the customer is always made aware and photos are provided to show damage or the reasons behind the recommended change.

Testing

With the equipment assembled its goes through the Testing Stage to ensure its working correctly and ready and fit for service.

Final Check

This final stage ensures the valve meets the customers requirements and that it has been built back up to specification before signing the job off and the certification produced.